From an economic perspective, the most suitable type of cargo transport unit is the one which best harmonizes the volume-to-payload ratio of the container with the stowage factor of the cargo. This provides the best utilization of the space and weight constraints. Other aspects that must be considered when selecting a CTU include: Type of product, weight, center of gravity, substructure and load-bearing surfaces, type of packaging, permissible loading capacity and/or stackability, load securing options, and other similar aspects. The internal dimensions, door dimensions and other similar information can be obtained from the owners of the CTUs or the relevant leasing companies or can be taken from their prospectuses beforehand.

In all cases, the CTU should be inspected. Not only for reasons of cargo care, but also for reasons of liability and accident prevention. "EIR"s are usually used at the handover points. This abbreviation stands for Equipment Interchange Receipt. They are receipts for the handover of containers, trailers, chassis and similar cargo transport units and items of equipment. On the basis of a visual inspection, the EIR lists, or marks in the diagrams printed on the form, all defects found on a CTU, for instance. If an inspection reveals, for instance, that a container exhibits damage which has not previously been documented, the costs for restoring or repairing it must be borne by the person who was previously responsible for the container. Thorough inspection and true and accurate documentation must therefore be in the interests of all parties involved.

The CTU guidelines require a thorough inspection of the cargo transport units before they are packed. A number of issues are listed in the guidelines as a guide for visual inspection. For exterior inspection, the CTU guidelines prescribe the following:

2.1.1 The structural strength of a container depends to a great extent on the integrity of its main framework comprising the corner posts, corner fittings, main longitudinal and the top and bottom end transverse members which form the end frame. If there is evidence that the container is weakened, it should not be used.

|

|

Fractures on a container |

2.1.2 The walls, the floor and roof of a CTU should be in good condition, and not significantly distorted.

|

|

|

|

| |

These containers may not be packed. |

|

|

Slightly deformed container

side walls |

This container can still be used. However, the distortion must be recorded in the EIR, the Equipment Interchange Receipt.

|

|

|

| |

Doors in a technically sound state |

2.1.3 The doors of a CTU should work properly and be capable of being securely locked and sealed in the closed position, and properly secured in the open position. Door gaskets and weather strips should be in good condition.

If containers are placed on an uneven surface, they become distorted. It is then only possible to open and close the doors with force. Fork-lift trucks are frequently misused in this way. "Dirty tricks" like this must be avoided. Unevenness of the ground or underlying surface must be leveled out before setting down the containers - possibly by using simple aids such as hardwood strips.

|

|

|

Top:

Plate as per UIC leaflet

on a swap-body |

Left:

CSC plate |

2.1.4 A container on international voyages should be affixed with a current International Convention for Safe Containers (CSC) Safety Approval Plate. A swap-body may be required to have a yellow code plate, fixed at its side wall (for details see UIC leaflet 596), which proves that it has been codified in conformity with the safety rules of European railways. Such swap-bodies need not be affixed with a CSC plate, but many of them will have one in addition to the yellow code plate.

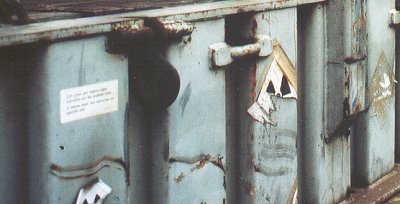

2.1.5 Irrelevant labels, placards, marks or signs should be removed or masked.

|

|

| |

Placards which have not been completely removed can lead to mistakes! Are they still valid after all? |

|

|

Lashing point on a semi-trailer |

2.1.6 A vehicle should be provided with lashing points for securing it aboard ships (refer to ISO 9367-1: "Lashing and securing arrangements on road vehicles for sea transportation on Ro/Ro ships - General requirements - Part 1: Commercial vehicles and combinations of vehicles, semi-trailers excluded" and to ISO 9367-2: Lashing and securing arrangements on road vehicles for sea transportation on Ro/Ro ships - General requirements - Part 2: Semi-trailers".)

|

Canvas covers |

|

2.1.7 When canvas covers are used, they should be checked as being in satisfactory condition and capable of being secured. Loops or eyes in such canvas which take the fastening ropes, as well as the ropes themselves, must be in good condition.

|

|

Loading a

swap-body |

2.1.8 When loading swap-bodies, it should be borne in mind that in most cases, the bottom and floor of swap-bodies are the main areas of their structural strength.

Checking vehicles includes checking the loading area, the side walls, the locking equipment, the support legs, the load securing devices, the supports used to guide the cover, the slats used to guide the cover, the canvas covers and the section where canvas cover is closed.

When performing an interior inspection, the CTU guidelines stipulate the following:

|

|

|

| |

Scrape marks on the roof of an O.T. |

Has this already rusted through? |

2.2.1 A CTU should be weatherproof unless it is so constructed that this is obviously not feasible. Previous patches or repairs should be carefully checked for possible leakage. Potential points of leakage may be detected by observing if any light enters a closed unit. In carrying out this check, care should be taken to ensure that no person becomes locked inside a unit.

There was one case in which employees locked a colleague inside a container during a check before a work break as a practical joke. During the break, the container was then removed. The employee, who suffered from claustrophobia, then had a heart attack. Practical jokes of this kind must be severely sanctioned by the company.

|

|

|

| |

Crack in a container |

Hole in a plywood container |

2.2.2 A CTU should be free from major damage, with no broken flooring or protrusions such as nails, bolts, special fittings, etc. which could cause injury to persons or damage to the cargo.

2.2.3 Cargo tie-down cleats or rings, where provided, should be in good condition and well anchored. If heavy items of cargo are to be secured in a CTU, the forwarder or shipping agent should be contacted for information about the cleat strength and appropriate action taken.

|

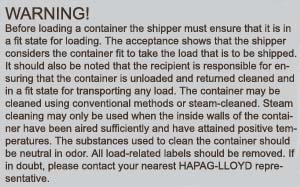

Notice regarding the fitness for loading of a container |

|

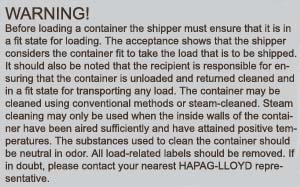

2.2.4 A CTU should be clean, dry and free of residue and persistent odors from previous cargo.

This point in the CTU guidelines relates to the fitness for loading of cargo transport units. For further information on this subject, see the section on "Preparatory work".

2.2.5 A folding CTU with movable or removable main components should be correctly assembled. Care should be taken to ensure that removable parts not in use are packed and secured inside the unit.

This is particularly important for flatracks. Notices describing how to set up and fold these CTUs safely are generally attached to these containers. For further information, see the section "Other markings".

|