Automobiles in containers

Compared with other cargoes, automobiles are considered a very light container cargo. The mass of an automobile constitutes only a fraction of the payload of the container. The rubber tires are a great advantage with regard to cargo securing, with coefficients of sliding friction ranging from at least μ = 0.4 to μ = 0.8 as a function of the container floor. Even with assumed accelerations of 1 g in the longitudinal and transverse directions, securing forces of only 200 - 600 daN would be necessary per metric ton of cargo mass.

As far as the "fitness for loading of the container" is concerned, particular care needs to be taken to ensure that no sharp-edged or pointed objects have been left in or on the floor which could damage the tires. No materials with a relatively high moisture content, such as lumber etc., should be in the container with the automobile. Condensation could cause mold to appear on upholstery etc. or other damage.

When opening containers packed with road vehicles, it should be ensured that no sparks are produced and that there are no naked flames in the vicinity, as leaking fuel could have created an explosive mixture in the container. Access to such containers should therefore only be permitted after thorough ventilation.

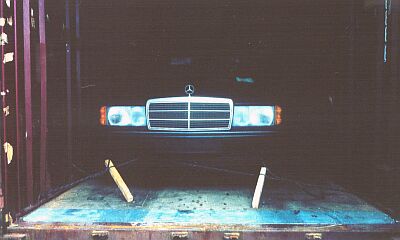

If vehicles are driven directly into containers, space must be left for getting in and out. The vehicles have therefore to be driven up relatively closely against one of the container walls (the right-hand container wall in the case of left-hand drive vehicles). However, enough space must be left to rule out the chance of contact with the container walls even if the vehicle structure sways.

|

||

| Lashed automobile in a 20' box container - plan view |

||

The ideal positions for lashing points on a vehicle are shown in the Figure. In practice they are not generally in these positions.

To achieve a uniform lashing angle, the fastening points on left-hand drive vehicles would have to be fitted symmetrically at front and back but somewhat eccentrically relative to the left-hand side of the vehicle. On right-hand drive vehicles, which would have to be driven up close to the left-hand container wall, the lashing points would have to be arranged somewhat to the right of center.

|

|

|

| Lashed automobile in a 20' box container viewed from the door end and the front end wall |

||

Very often, vehicles only have inappropriately fitted tow eyes as lashing points, for example back right and front right, back left and front right and similar combinations. If this is the case, the lashing angles with which an automobile is secured in a container are inevitably different.

|

|

|

|

| Asymmetrical lashing angles resulting from inappropriate arrangement of tow eyes or lashing points |

||

However, damage is most frequently caused to automobiles in containers not as a result of inadequate securing but as a result of carelessness during driving in and out and during working in the cramped conditions inside the container.

For various reasons, sufficiently stable and/or easily accessible lashing points are often not present on vehicles. Moreover, the preparatory work carried out on vehicles, such as covering the driver's seat with protective film, does not in practice meet current requirements. Here is an example:

|

||

| Automobile securing with unfavorable angles | ||

The lashing points on the vehicle would have ensured uniform angles, if the vehicle had been driven forward into the container. However, the vehicle was intended for South America, where vehicles are often damaged during reversing out of the container. The shipowner thus specified that the vehicles were to be reversed into the container in Germany. Since it is also a requirement that the driver get in and out through the driver's door only, and only the driver's side was protected by a film covering, it was only possible to drive the vehicle so its right-hand side was against the left-hand container wall. If the lashing points had been fitted symmetrically and at the same time the passenger side had been covered with film, such vehicles could be parked against the right-hand container side: symmetrical lashing angles would be the positive result.

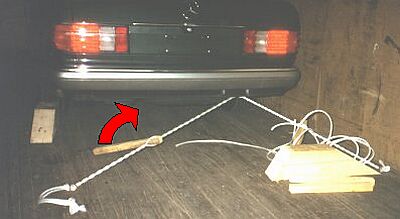

"Hercules" rope interwoven with polypropylene was used for securing by means of a "Spanish windlass", which is an extremely reliable and quick method. However, it is extremely important for the tightening spar to be secured against coming undone.

|

||

| Incorrect use of a tightening spar | ||

The left-hand tightening spar is positioned centrally. The rope turns are evenly distributed on both sides, as they should be, but the winding could come undone. The tightening spar should therefore have been longer. The wooden members or wedges have no business to be in the container. Blocking wheels with wedges or lumber nailed laterally against the wheels does not constitute sensible cargo securing, since there is too great a risk that the tires will be damaged when the material is inserted or that the tools used will damage the paintwork or make small dents.

|

||

| Unfavorable angles - tightening spar not secured against coming undone - use of wheel wedges |

||

The wooden wedge, which has moreover been incorrectly cut, has no doubt been used because the lashings have a very small longitudinal component.

|

||

| More favorable transverse components due to the existence of two lashing points on the automobile |

||

If the automobile had two lashing points at front and back, it could be far better secured than when only one lashing point is available at each end.

|

||

| Longitudinal components improved by different positioning of tow eyes |

||

Two lashing points at front and back allow greater flexibility in the fixing of lashings.

N.B. With all of the above methods, there is a risk of the tightening spar coming undone. If this risk cannot be combatted, the use of prefabricated rapid-tightening systems is recommended. However, using them is more cost-intensive.

|

|

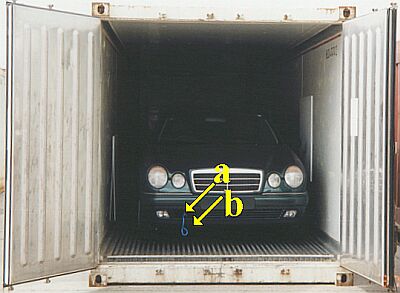

Above and selective enlargement to the left: Automobile in a refrigerated container: "modern" securing hooks |

Many lashing lugs (a) are hidden behind removable flaps. Lashing hooks (b) have to be hung in these hidden lashing lugs (a) for lashing the vehicles.

|

|

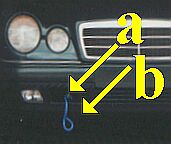

Above and selective enlargement to the left: Risk of damage due to "modern" lashing hooks |

Because of these hooks, in which two lashings have to be hooked and fastened, the vehicle has a degree of "play" to the left and right (see red arrows) and can move to and fro.

It should be pointed out that such impractical methods are used by a very large number of automobile manufacturers, many being very much less suitable than those described here. Many automobiles do not have any lashing points and have to be lashed by the wheel rims.

If two hooks could be fixed to the lashing lugs, vehicles would be fixed appropriately by the lashing means used, provided that the angles and resultant force components conform to shipping stresses.

|

|

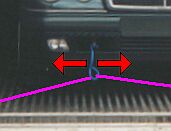

Above and selective enlargement to the left: possible method of fixing a vehicle using two lashing hooks in the lashing lug |

|

|

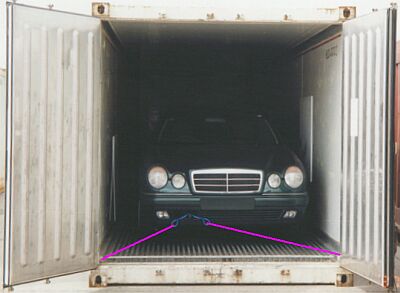

Above and selective enlargement to the left: sensibly fitted lashing lugs and hooks |

With two lashing lugs and hooks at back and front, the vehicles would be appropriately equipped for securing.