| The most important objective when bundling cut and packaged lumber is to ensure that the materials used for bundling, generally steel strapping, cannot be damaged by handling with forklift trucks and lifting gear. Therefore, only lumber with a routed-out groove should be used as a support. |  |

| Expertly fashioned supports |

Steel strapping has very little elasticity. This shortcoming may be compensated, for example, by using edge protectors of a material with good recovery. Otherwise, the strapping regularly slackens, since the steel strapping presses into the wood and becomes loose as a result of the reduction in circumference. Steel strapping can only be recommended if it is used in conjunction with such materials. Otherwise, materials should be used which have good, but not excessive, elasticity.

|

|

| Normally arranged strapped packages |

If packages with the usual transverse strapping are moved lengthwise, they should additionally have skids, so that the straps are not torn off during handling.

|

|

| Well organized package base |

Here, the lengthwise members have been recessed and the transverse members let into the recesses. In addition, further transverse members have been fitted and the ends of the lengthwise members cut in the manner of skids. All the wooden members have been positioned in such a way that there was no risk of the strapping being damaged by forklift trucks, and also in such a way that lifting gear can be used for lift-on/lift-off operation.

|

|

| Risk of damage due to inappropriate strapping |

Strapping is not suitable for the handling method shown here. The strapping could tear during packing and unpacking, resulting in delays and extra costs.

|

|

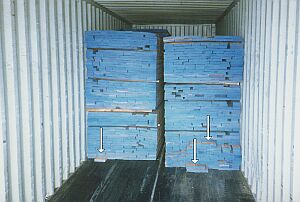

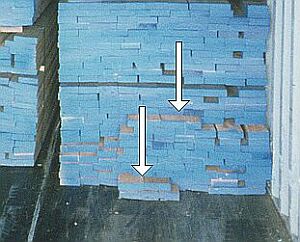

| Cut lumber packages in a box container, enlarged section |

It should be noted that the strapping did not withstand the stresses of handling even during loading.

|

|

| Stowage gaps filled with squared lumber |

For trouble-free transport it is important for all gaps to be filled.

If stowage gaps are not filled, the goods will be displaced during transport, possibly resulting in damage to the container and/or goods.

|

As may be seen from this import container, financial losses are the ultimate result of impeded handling, storage after shipment and onward transportation. | |

| Losses result if gaps are left. |

Strapping deficiencies and unfilled gaps regularly lead to deformation of packages.

| Cargo slippage due to weak strapping and unfilled gaps |  |