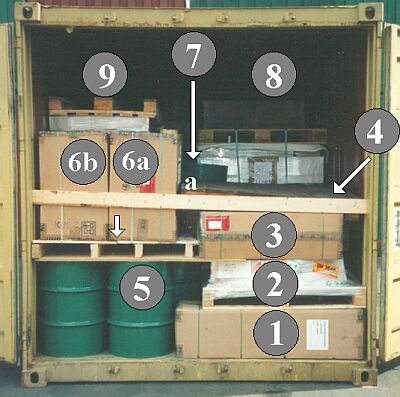

At first glance, this container looks properly packed.

|

||

| 20' box container with packaging and packing deficiencies | ||

On closer inspection, however, a whole series of deficiencies becomes apparent, which are mainly caused by inadequate packaging of the goods.

|

||

| Labeling of the packaging and packing deficiencies | ||

Package (1) is exposed to excessive stress during transport by (2) and (3), because there is no interlayer dunnage. Pallet (2) is not packed flush and has therefore been unfavorably wrapped. Package (3) is inadequately marked, lacking the two upright arrows symbolizing "keep upright". In the case of corrugated board cartons this marking is necessary, because the carton is only sufficiently strong if its corrugations are upright. Since it has not been appropriately marked, the carton has been laid horizontally. The pallet (4) positioned thereon is in a position to exert inadmissible pressures on the packages (6a-b) at (a). A positive feature is that interlayer dunnage of chipboard has been laid on the barrels (5). Package (6) has not been strapped flush on two pallet-like supports. In effect, it consists of two independent packages: namely (6a) and (6b). A pallet has been fastened to the top of package (9), so rendering overstowing impossible without additional pressure-distributing measures. The barrels (7) have been unfavorably packed, causing gaps in the cargo.

In total, these deficiencies increase the stowage factor of the cargo and generally complicate packing and utilization of containers.