Wood mainly consists of elongate, firmly intertwined, microscopically small cells. These cells consist of a cell wall and a cell lumen, as a result of which wood is a pore-filled material primarily consisting of cellulose, hemicellulose, lignin and water.

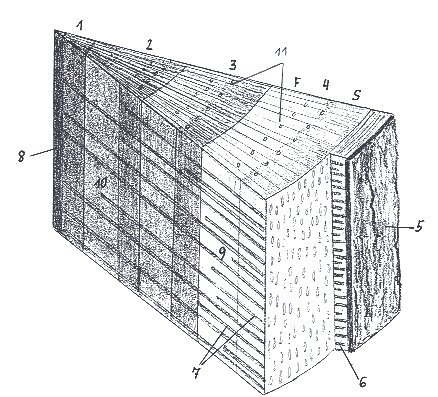

| Figure 166: Segment from a four year old pine; Schmeil [50]

|

Figure 166 shows the macroscopic structure. In addition to the bark and phloem layers, the soft sapwood layers and the hard heartwood layers can also be distinguished. The soft, light-colored sapwood consists of living cells and transports water and nutrients, processes which occur in the outermost annual rings. The hard heartwood consists of dead cells and is often of a dark color due to the deposition of heartwood substances, such as tannins and colorants, resins and other lumber constituents, as well as storage materials. In comparison to sapwood, heartwood has a lower water content, is heavier, harder and more durable.

- Trees with a large proportion of heartwood are known as heartwood trees, for example mahogany, cedar and oak (see Fig. 167).

- Sapwood trees which exhibit no difference in color and water content between the inner and outer wood are, for example, birch, willow and lime.

- Dressed lumber is lumber from which the sapwood has been removed. Sapwood is highly susceptible to insect attack, while heartwood is less so.

|

Figure 167: Makore: tropical roundwood from West Africa with black, reasonably insect-resistant heartwood (inside) and light-colored sapwood (outside) susceptible to fungal and insect attack; Photo: U. Scharnow |

Bark is the outer sealing tissue of trees, which primarily produces cork. The outer tissue layers die and then form the bark. The bark of some trees provides valuable goods, e.g. tannins (acacia, Brazil wood and oak bark), spices (cinnamon), pharmaceuticals (cinchona bark, cascara, quebracho bark) and cork (cork oak) (see Fig. 168).

| Figure 168: Cork bark from the cork oak (Quercus suber); Photo: U. Scharnow |

|

Lumber and bark have water contents of approx. 4 to 30% and belong in water content class 2 (WCC 2).

They are goods displaying 3rd order biotic activity (BA 3), because their respiration processes are suspended but their biochemical, microbial and other decomposition processes still proceed.

Roundwood is frequently transported while green and thus with very high moisture levels. If several of these containers are loaded in one hold, elevated CO2 concentrations or oxygen shortages may arise as a result of decomposition processes.

Requirements with regard to storage climate conditions are dependent on the range of shapes carried and the packaging used, which may range from loose transport to transport in crates or cases (bark also in bags and bales), i.e. some products may be exposed without protection to atmospheric influences while others require particular temperature humidity/moisture and possibly ventilation conditions (SC VI).

In connection with this, fitness for container transport has also to be assessed and extends from lo/lo transport using open-top containers through flatracks, platforms to standard containers and special containers ("logtainers").

Special export and import certificates are often required for lumber and especially tropical lumber. These certificates prove, for example, that the lumber has been felled from a managed forest and guarantee that the it originates from forestry operations which have been certified to operate responsibly by an independent and recognized certification organization.

Transport instructions and damage

All types of lumber, whether processed or unprocessed, are carried in containers. Lumber is transported as roundwood (round lumber, log, see Fig. 169) and cut lumber (see Fig. 170).

|

|

| Figure 169: Roundwood, strapped together into bundles; Photo: U. Scharnow |

Figure 170: Cut lumber, strapped together into packages; Photo: U. Scharnow |

Veneers and sheets are transported in cases, crates or steel strapping with edge protection or on pallets. Veneers are thin sheets of lumber 0.6 - 6.0 mm thick used as a decorative covering for furniture. Veneers are a valuable cargo, especially when produced from rare or exotic wood species.

Bark is transported in bags, bales, barrels and cases.

Hygroscopicity

Due to lumber's high pore content, it is regarded as a porous material having lumens filled with water or water vapor. Lumber is classified as follows on the basis of its water content (Table 27).

| Designation | Water content in % |

| Kiln dry lumber | 0 - 6 |

| Room dry lumber | 6 - 10 |

| Very dry lumber | 10 - 12 |

| Air dry lumber | 12 - 15 |

| Slightly dry lumber | 15 - 20 |

| Green lumber (forest dry) | 20 - 25 |

| Fiber saturated lumber | 30 - 33 |

| Water saturated lumber | > 33 |

Table 27: Water content of lumber in %

Fiber saturation means that the cell walls are maximally filled with water, while water saturation means that all lumens are maximally filled with water.

Air dry lumber is considered dry for shipment; its equilibrium moisture content is

70 - 80% at a temperature of 20°C (see Fig. 171).

|

Figure 171: Sorption isotherm for lumber, air dry (20°C) |

Bark must be protected in particular from all forms of moisture (seawater, rain, condensation water), since it tends easily to mold growth and spoilage. The water content of cork bark, for example, is 4 - 5%, while the equilibrium moisture content is 65 - 70% at 20°C.

The lumber "works", i.e. swells as it absorbs moisture and shrinks as it dries. Storage in the sun may cause dry splitting due to drying as result of solar radiation.

If palletized veneers exhibit moisture damage from the outside only, a leak may have occurred. If the container was checked for leaks before acceptance of the load, it may be assumed that the damage occurred during prior storage or due to dripping sweat in the container.

Exposure to humidity/moisture may cause veneers in particular to develop a tendency to waviness and to degluing of sheets.

There are three causes for waviness of veneer:

- If the veneers are dry and also exhibit no moisture stains, a production error (excessively rapid drying) may have been the cause.

- If stains and rings are visible, but the veneer is nevertheless dry and wavy, it is to be suspected that the veneer has become damp during storage prior to container transport and has redried.

- If the veneer is still wet and wavy, the damage may have occurred during transport or storage. In the latter case, the truck or container must have been leaky or loading was carried out in rain. The more tightly are the veneers compressed on the pallets, the lower is their sensitivity to external influences.

Density

A distinction is drawn between theoretical density and apparent density. Theoretical density is calculated purely on the basis of solid lumber, i.e. as if all cavities within a slab of lumber had been obliterated by compaction. Theoretical density is identical for all species of wood and is 1.50 g/ cm³. Apparent density or bulk density is calculated from the weight and the volume of the lumber and differs from species to species in accordance with their differing structure. Comparisons can only be made between types of lumber with an identical water content. Fixed points are a water content of 0% (kiln dry lumber) and 15% (air dry lumber, see also Table 28).

| Category | Density in g/cm³ |

| very light species | < 0.40 |

| moderately light species | 0.41 - 0.50 |

| light species | 0.51 - 0.60 |

| moderately heavy species | 0.61 - 0.70 |

| heavy species | 0.71 - 0.80 |

| very heavy species | > 0.80 |

Table 28: Classification of lumber types by density

Balsawood with a density of 0.14 - 0.44 g/ cm³ is the lightest lumber, while quebracho (1.12 g/ cm³), ebony (1.18 - 1.33 g/ cm³) and guayac (1.20 - 1.30 g/ cm³) are among the very heavy species.

Measures for maintaining quality

To protect lumber from damage

- mechanical means and

- chemical lumber preservatives

Sheet steel protectors are applied around the cross-section of the log in order to prevent splitting due to drying-out of the lumber. In the case of woods with a high tannin content, however, this may result in oxidative discoloration. In order to inhibit splitting, oxidative discoloration and fungal attack, the cross-sections or bark-free surfaces of the logs are preserved immediately after felling with wax, paraffin, latex or lime, e.g. limba, Parana pine; limba is generally limed.

Damage

Mechanical damage

Splitting due to shrinkage caused by drying-out degrades quality considerably. There is a risk of frost splitting at temperatures below freezing point, e.g. in the case of ilomba and African canarium.

Lumber is at the greatest risk of mechanical damage when being packed into and unpacked from the container. In addition, inadequate cargo securing very often leads to damage to sensitive edges and corners of veneer packages. To prevent mechanical damage to the packages, fit for purpose packaging is absolutely essential, as is correct and proper handling of the goods. Particular attention should be paid here to edge protection and modular unit load dimensions. Correct edge protection ensures that the veneers survive undamaged slightly rough handling during packing and unpacking. Container modularity ensures tight packing of a container and thus allows the cargo to be secured for the most part without additional expenditure.

The packages should have bases that resemble pallets, so that they can be readily handled using ground conveyors. If packages have to be packed lengthwise into the container, it must be ensured that ground conveyors can gain access under the pallet bases even from the narrow side. This ensures that it is possible to avoid any damage arising from "pushing" or "pulling" of the packages.

Hazards to health

Over 30 different types of lumber contain irritants or poisons, e.g. khaya, African padouk, amarante, beté, jarra wood, guayac, makore. Care must be taken in the event of splinter injury owing to the risk of skin inflammation (dermatitis).

Damage caused by pests and fungal attack

Insect infestation

The nature and duration of non-containerized precarriage have a major impact on the quality of tropical structural lumbers due to pests and fungal attack.

"Worminess" is the result of burrowing by wood-destroying insects (beetles, horntails and wood borers). The soft sapwood is particularly susceptible. Dressed lumber is consequently not at such high a risk.

Particular attention must be paid to termite infestation of tropical roundwood. Termite-infested lumber has "galleries" or tunnel-like systems of passageways. Imported exotic hardwood logs must always be inspected for termite infestation. Termite-resistant wood species are, for example, jarrah, East-Indian rosewood, teak and izombé.

Fungal attack

Fungi which may attack tropical structural lumber include

- wood-destroying fungi, which may cause "white rot", "red rot" and "brown pocket rot", and

- wood-discoloring fungi, which cause blue discoloration, among other things.

| Optimum temperature | Water content for lower growth threshold |

Optimum equilibrium moisture content |

|

| Blue stain fungi | 27 - 30°C (max. 35°C) |

30 % (fiber saturation point) |

85 - 95 % |

| Wood-destroying fungi | 33 - 40°C | 20°C | 85 - 95 % |

| Hygrophilic molds | 37°C | moist to wet surfaces | 95 - 99 % |

| Wood-destroying insects | 27 - 30°C | at least 15% air in pores of the lumber | > 75% |

Table 29: Optimum temperature and humidity/moisture requirements of

wood-damaging fungi and insects

|

Figure 172: Breakwater pile of pinewood, destroyed by pile- or shipworm (Teredo navalis); Photo: Ragna Scharnow |

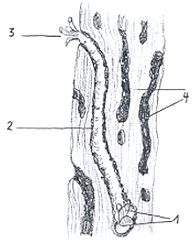

Figure 173: Pile- or shipworm (Teredo navalis)

|

|

Rafted logs may be infested by bivalves and crustaceans (e.g. balanids). Destruction of the lumber by bivalve teredos proceeds very rapidly due to the large number of individuals (see Figs. 172, 173). Only few wood species are considered teredo-resistant, e.g. ekki, teak and acariquara (see Fig. 174). The latter are therefore used for breakwater construction.

|

| Figure 174: Acariquara logs from Brazil, which are teredo- and salt water-resistant, have a fibrous structure and cavities. Several of the logs are strapped together into bundles. Photo: U. Scharnow |