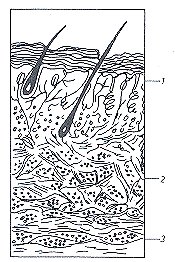

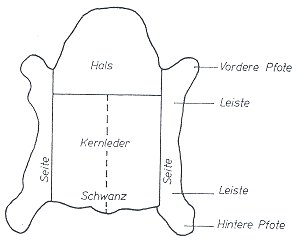

Hides are the raw material for the production of leather. Fig. 186 shows the structure of an animal hide. It is the dermis, which primarily consists of protein fibers, which forms the actual leather after removal of the epidermis and the subcutaneous tissue. Fig. 187 shows the component parts of a hide. The chemical composition of a green hide is: water 65%, protein 33%, fat 0.2 - 2% and mineral salts approx. 0.3%.

|

Figure 186: Section through an animal hide [27] 1 - Epidermis with hair 2- Dermis 3 - Subcutaneous connective tissue |

| Figure 187: Component parts of an animal hide; Budzynska [7] |

|

After removal from the body, the hide of large animals, such as cattle, buffaloes, horses and pigs, is generally preserved by drying or salting prior to further processing. Increasingly, it is the beamhouse product, i.e. the animal hide from which the epidermis and hairs and subcutaneous connective tissue have been removed, which is traded; this product is preserved by pretanning before it is sold.

Furs are the hides/furs of smaller animals, e.g. goats, sheep (lambs), foals, calves. The winter fur is fully mature, generally with a dense hair cover and thin leather; the summer fur has sparser hair and thicker leather. Furs are also preserved by drying, salting, curing or pickling.

Prime furs are valuable hides/furs of smaller animals, e.g. sable, mink, chinchilla, fox (red, blue, silver fox), Persian lamb, seal, otter, marten, ermine, muskrat, nutria.

Leathers are finished or dressed animal hides which have been subjected to tanning processes and are also known as "wet blue leather". Leather can be classed by hardness, ranging from hard leather for shoe soles to soft leathers for fashion accessories.

With low water contents of 10 - 30%, hides, furs and leather belong to water content class 2 (WCC 2). Due to their processing, fibers belong to the class of goods in which respiration processes are suspended, but in which biochemical, microbial and other decomposition processes still proceed; they thus exhibit 3rd order biotic activity (BA 3). They require particular temperature, humidity/moisture and possibly ventilation conditions (SC VI).

Furs and leather goods are transported in standard containers, subject to compliance with limits for water content of goods, packaging and container floor.

Methods for preserving hides

Due to the chemical composition of hides and fur which is favorable for bacterial and fungal growth, these goods are subject to rapid biological decomposition (rot, mold growth and mildew stains), which is associated with self-heating. They are thus preserved before transport; the commonest methods are

- drying

- dry salting

- wet salting

Transport instructions and damage

Packaging

Hides and furs are transported in bundles, packs or bales, while wet-salted hides are also carried in barrels or solid wooden cases lined with sheet metal or plastic film. Bales are usually compressed and tied with stainless steel or insulated wire. Leather is transported in bags, bales or cases, while finished products are shipped in cartons etc. or even in sales packaging.

Self-heating

Due to their chemical composition, hides and furs have a tendency to self-heating and spontaneous combustion. This behavior is partly determined by the natural fat content, which varies greatly as a function of animal species, breed, climate and nutrition.

| Cattle hides | approx. 0.5 - 2% |

| Pig hides | approx. 5 - 30% |

| Goatskins | approx. 3 - 10% |

| Sheepskins | approx. 10 - 40% |

Table 35: Fat content of animal hides/skins

Due to the effect of heat and moisture and the impossibility of providing ventilation in standard containers, heat may build up, such that autoxidation processes resulting in self-heating may occur.

Optimum transport temperatures are 18 - 23°C.

Action of moisture

Exposure to moisture may result in rot, mold, mildew stains and hair loss in hides. The water contents of hides and furs are within the range 10 - 15% for dried furs, 15 - 20% for dry salted hides, 20 - 30% for wet salted hides and 12 - 17% for leather.

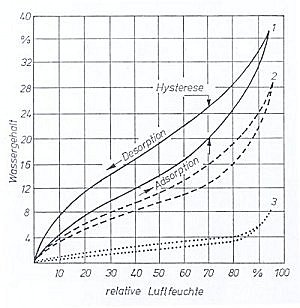

If storage conditions are excessively moist, i.e. at relative humidities of > 75%, leather tends to grow mold and suffer spoilage, while metal components (eyelets, buckles) on leather gloves and shoes will corrode (see Fig. 188).

|

Key: |

| Figure 188: Sorption isotherms for leather [27] 1 - Box cow/calf leather 2 - Vegetable/synthetic tanned cow and pig sole leather 3 - Foamed synthetic leather |

|

If storage conditions for leather goods are excessively dry, i.e. at relative humidities of < 55%, drying damage may result in brittleness and cracking, which may give rise to complaints. Severe drying-out results in shrinkage in mass.

Contamination

Rust damage occurs after brief contact, especially with iron/steel. Containers must be completely clean, as contaminants could react with the hides. The painted finish of the container interior must be absolutely intact as contact with iron/steel components may result in reactions and irreversible damage. Containers with a special floor coating may have to be used as the strong smelling residues from hides are impossible to remove from a "normal" container floor.

Mechanical damage

Such damage often takes the form of snagging, which may be the result of improper handling. Incorrect stowage methods may result in kinking and creasing in dried hides.

Insect infestation and pathogens

In the event of moisture damage, look out for the development of maggots. Insect infestation may occur during precarriage or during brief storage prior to container packing. Maggots and beetle chewing damage result in serious damage to the hides. Hides may also contain anthrax spores. Appropriate certificates may be required.