|

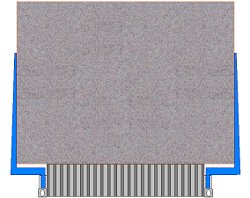

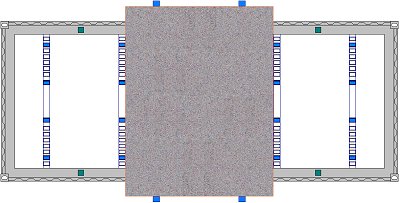

Compact loading in a box container |

This method of packing may also be described as a complete longitudinal and transverse block. All the inertia forces acting on the load are transferred directly by the load to the components of the means of transport. The prerequisite is that the components of the transport unit are capable of withstanding such forces long-term.

|

A virtually complete compact load of cases in a container |

Goods can often be packed successfully against the end walls and the sides. If the packages do not fill the entire length of the container, appropriate securing mechanisms should be used in the door area. If there is a risk of the packages working loose from the block as a result of the movement of the ship, then additional lumber bracing or other similar securing mechanisms should also be applied on top of the load.

|

|

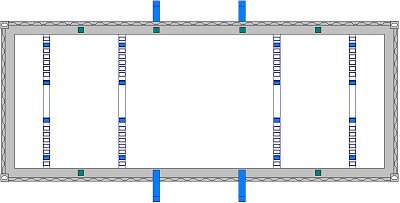

| Tight-fit for special receptacles traveling on a special flatrack |

|

The half height open top containers in situ, as seen from the end |

The flatracks shown here were specially designed to accommodate stacked receptacles. They are used to deliver securing elements such as stacking cones, twist locks, bridge fittings and other similar items used for securing containers on board ships. Solutions of this type are also suitable for transporting other small items. Taking into account the costs of packing and securing items, the use of a more expensive special container may, in the long run, actually pay for itself, particularly as the half-height saves on transport volume.

Platform containers of normal construction can usually be loaded in a compact/tight-fit fashion if the dimensions of the load are identical to the dimensions of the container loading area:

|

|

| Compact stowage of a case on a flatrack with stanchions |

This constellation is very rarely seen in practice. Shortcuts are not permitted in the field of load securing, but if the intended dimensions of a case are very close to those of the loading area of a real flatrack then it is possible to make the case fit the flatrack by building it slightly larger than originally planned. The additional costs invested in building the case are recouped by the costs saved on securing the case, and the risks of carriage are also lower.

|

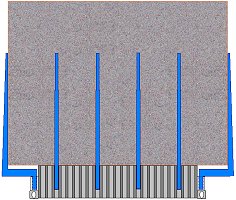

Compact tight-fit securing of a power substation using specially shaped stanchions crosswise on a flatrack |

The load shown here is a substation. An overwidth such as this would normally require a considerable load securing outlay. The adjustable stanchions shown in blue (and which must be specially manufactured) can be used to ensure an excellent lateral tight fit. In reality, cargo items are not so large that they reach as far as the end walls. In this case, therefore, they would need to be braced with wooden beams or similar material. Securing by lashing would be even more work-intensive. Even if the items to be sent were the same length as the container, the overwidth would prevent the cargo from being loaded hard up against the end walls since the container would no longer fit into the slots of the ship. A possible solution would be to use a flatrack with special stanchion pockets that allow the load to be secured as a tight-fit.

|

|

| Stanchion pockets on a specially designed flatrack |

|

Power substation secured using removable stanchions and adjustable stanchions - Side view |

|

|

| Power substation secured using removable stanchions and adjustable stanchions - Top view |

The means of transport are often only partially filled. Gaps may arise as a result of the characteristics of the load or for packing reasons. If so, then the load must be secured using the appropriate methods. Special securing measures may be required if there are edges on the means of transport or the edges available are not able to bear the load, as is the case when using partially open/open means of transport. In these cases, other methods will need to be used. These are described in the following sections.