|

Incorrect securing by filling |

Compact packing and filling of gaps can only be implemented effectively if all parts of the load are sufficiently robust. Here, for example, the movement of the ship and the container while at sea would, sooner or later, destroy the cartons that are marked fragile. The gaps that occur as a result of this would then put the wooden cases at risk. The fact that the upper of the two cartons has been loaded upside down is not particularly good, but it is also not forbidden. If the shipper wishes to ensure that a packaged item is transported upright, it must be marked accordingly.

|

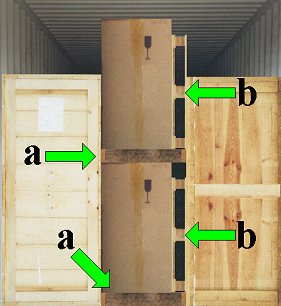

Correct filling of spaces |

The gap has been left between the two strong wooden cases and filled in using boards and squared lumber (a). The cartons were loaded into this space. The remaining spaces were filled in using old pallets (b). The forces acting on the wooden cases are transferred from case to case by the squared lumber and onto the side walls of the container. The pallets are simply transferring the forces from the cartons to the case on the right.

An important note referring to the use of "old materials" is given in section 3.2.12 of the CTU guidelines.

- When deciding on packaging and cargo-securing material, it should be borne in mind that some countries enforce a garbage- and litter-avoidance policy. This may lead to limitations on the use of certain materials and imply fees for the recovery of packaging at the reception point as well as similar problems for the shipper of the cargo. In such cases, reusable packaging and securing material should be used. Increasingly, countries are requiring timber dunnage and packaging materials to be debarked.

|

|

| Filling a space in the vicinity of the door |

|

The space remaining in the vicinity of the door is filled in using upended pallets placed across the space and squared lumber beams fitted into the corrugations of the container. Care must be taken if the overall mass of the load is large, since the use of this method could cause damage to the corrugations. If possible, the load should be braced against the door posts in the vicinity of the doors. If this is not possible, the door area can be filled in, but in such a way that the load is spread over a sufficient area that no harmful pressure points arise. |

|

|

| Corrugations run the risk of being damaged |

||

|

|

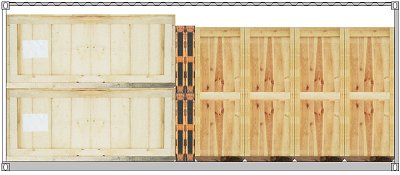

| Filling in space left in the middle of a container |

Leaving spaces in the middle of a container and filling them in requires the packer to calculate the required dimensions exactly. With good planning this is not a problem. There is an advantage to this, since it allows the distribution of weight to be better organized.

|

|

| Using airbags to fill in a space left in the middle of a container |

Since airbags should not be used in the vicinity of the door for safety reasons, the obvious option is to leave space in the middle of the container. The airbags can be affixed and partially inflated before loading the cases in the door area. Once the cases have been put into place, the left-hand door is closed and the airbags can be inflated fully.

|

|

| Impractical method of filling a gap in the middle of a container using airbags |

Theoretically it is possible to determine the size of the gap and to fully inflate the airbags before loading the boxes. However, this runs the risk of the airbags being crushed without the packers being able to monitor this, since the height of the cases means that the airbags are no longer accessible. This method of securing is practical when used with containers which have side doors and with platform containers which can be accessed from the side.