|

|

|

|

| Container floors | |||

Container floors generally have a thickness of just 25 - 30 mm. Also, the majority of floor types will be damaged by the use of nails. Thus, these methods cannot really be recommended for securing in containers. They could be used on softwood planking, as is sometimes used on platform containers, but are not suitable as the only form of securing for heavy goods. Another variation is to create an additional, strong, specially-designed base made of planks or squared lumber beams and driving nails into this.

|

Wooden beam 5 cm x 12 cm |

If the method is not used for light packages that are at risk of tipping, as it usually is, then it must be ensured that only top-quality wood is used, with a thickness of at least 50 mm. Top-quality in this case means, healthy, free from cracks and dry. Shear strength and extraction resistance are influenced by the diameter of the nails, the penetration through the wood, the penetration into the underlying surface, the angle at which the nail is driven in, and the properties of the nail surface. Nails with grooves or with coatings will have higher resistance than ordinary wire nails.

Experience suggests that a nail, 5 mm thick, that is driven in vertically and which penetrates through 50 mm of the grain side of a piece of wood, and is driven in to a depth of 40 mm can be expected to offer 400 daN of resistance. Our own testing suggests that this value can be halved for wet wood. If the nail is driven in along the grain the values can also be halved. The resistance values are also influenced by the pattern of nails in the wood and the distance between the nails.

|

|

|

|

||

| Securing using wooden beams | Nail strip for a nail gun |

Nails should always be driven in vertically or at a slight angle to the direction of loading. They should not be too close to the edge of the piece of wood, and should not run in a line along the grain. Nails can be driven in efficiently using a compressed air nail gun. Magazines of nails, either rolled or in strips provide a source of nails that can be used with very little physical effort.

When using wedges to secure loads, badly cut wedges are often selected. Basically, wedges should be cut and positioned in such a way that the long side of the wood, i.e. the grain side, is the side that is nailed, and not into the grain.

|

|

| Correctly cut wedge for securing cylindrical objects |

Wedges of this type are also called chocks, roll or pipe wedges. The critical factor is that the grain side of the wood is available to take the nails.

|

|

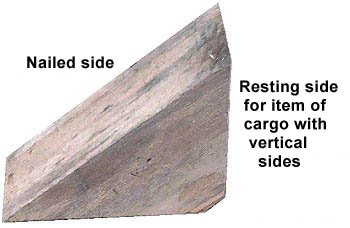

| When used as a wedge for loads with vertical surfaces: Wrong |

This is the same wedge, but now it is placed differently. If a packer were to use this to secure a case, they would need to drive a nail into the grain. The wedge would split either during nailing or on one of the first jolts during transportation. Tests have shown that when wedges are used incorrectly barely half of the resistance values are achieved than would be achieved if used correctly.

|

|

| (Almost) correctly cut wedge for goods with vertical surfaces |

A wedge of this nature can be referred to as a crate wedge. Here, it is obvious what is meant. The nail can be driven into the grain side - and rightly so. However the slope of the flank is too steep.

|

|

| Correctly cut crate wedge |

Here the slope of the flank is much better suited to the requirements of a crate wedge.

|

|

| When used as a wedge for cylindrical objects: Wrong |

If the crate wedge was to be turned the other way, it would make an incorrect pipe wedge.

| Sawing patterns for pipe wedges |

There is no waste material when cutting pipe wedges. Any flank angle is possible. The right angles are always at the outside edge of the piece of wood.

| Sawing patterns for crate wedges |

When cutting crate wedges, make one cut at the required flank angle and then continue at right angles. Any flank angle is possible. The steeper the starting angle, the slimmer the wedge. The right angles are always on the inside of the piece of wood.

If the packers are using wedges for both cylindrical and right-angled loads, a plentiful supply of both types should be made available.

|

|

|

| Pallet with pipe wedges | Pallet with crate wedges |

As a general rule, however, very little attention is paid to the instructions described here:

|

Incorrectly cut crate wedges, or pipe wedges used as crate wedges |

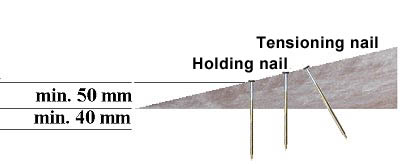

It can be seen clearly that the wedges have already started to split. The function and effectiveness of the nails are to be doubted. They appear to be located too high up to fulfill the following requirements: For each wedge, at least three nails are necessary, one tension nail and two to hold the wedge in place.

|

|

| Minimum conditions for nailing wedges and boards |

The tension nails have the task of pulling the boards and wedges close to the load in order to eliminate any damaging gaps.

|

|

| Nails in boards (left: holding nails, right: tension nails) |

With boards, the nails can also be driven in against the direction of loading.

|

|

| Wedge-shaped board cut to fit |

This type of securing with wood is not usually capable of achieving the result expected of it.

|

Securing that has no effect |

This form of board is not able to counteract the nail being lifted out of the floor.

|

Wrong type of wedge, in the wrong place |

This wedge has been cut incorrectly. It has thus already split as a result of a hammer blow or a jolt during transportation. The effective height is too small, the nails can easily be levered out.

|

|

| Incorrectly cut wedges |

|

|

| Incorrectly cut wedges |

|

Correctly cut wedges - but insufficient securing |

|

|

|

| Simulation of a 30° roll angle of a vessel | ||

|

|

|

| Radial wedges | Tank wedge with a nose for the nail |

Specially designed wedges of a variety of shapes can be used to secure special types of load. The securing effect is achieved by the shape of the wedge itself. The nails serve purely to hold the wedge in place.