Half-shells on a 20' flatrack

|

||

| Inadequate securing of half-shells on a 20' flatrack | ||

The half-shells lie relatively neatly on cradles but cannot be held securely in position by the steel strap lashing spanning them crosswise. The wooden bracing between the two stacks of half-shells was no doubt put in place with good intentions, but will not hold under likely shipping stresses.

|

||

| Adequate securing of the half-shells on the flatrack | ||

The easiest securing option is to fit symmetrical direct lashing using claws which engage in the shell stack from above.

The cradle takes the form of a simple cross-bed, the top layer of which consists of squared lumber providing an edge of uniform height which allows the half-shells to be positioned in form-fitting manner thereon.

|

|

||

| Simple cross-bed | Simple cross-bed, lined | ||

| (in each case in plan view and with corresponding side views) | |||

If dimensions allow, half-height open-top containers are suitable for transporting such goods:

|

||

| Partial view of a half-height open-top container | ||

The effort involved in securing is kept within limits, since compact stowage can be achieved using simple wooden lattices and bracing. Reasonably priced, unsquared wooden dunnage and laths can be used to secure the cargo to the solid sides of the container.

|

||

| Preparation of reasonably priced securing lumber | ||

The boards (a) and (b) are nailed to one another crosswise. The laths (c) are attached parallel to the outer boards (b). The overall thickness of the boards must match the size of the gaps between half-shells and container side. If the gaps are relatively large, planks may be used instead of the boards or the boards can be adjusted to fit the gaps with additional squared lumber.

|

||

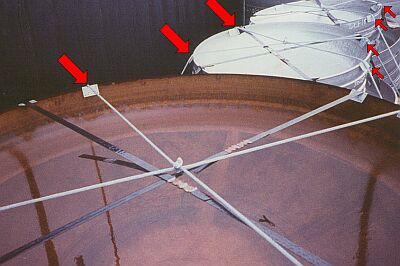

| Top and selective enlargement below: Securing of half-shells in a "half-height open-top container" |

||

Bracing is placed in the gap between the stacks of half-shells. Lengthwise wooden members (e) are used on crosswise nailed boards or laths (d) as bracing. These members cannot become laterally dislodged; however, if it is felt that there is a risk of their doing so, additional laths (f) or boards should be fitted, which are arranged as X-bracing, as shown in the detailed view below.

|

||

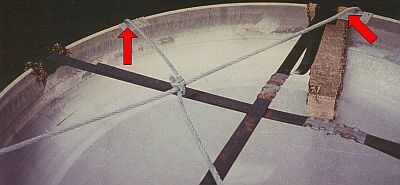

| Detailed view of wooden bracing and X-bracing (g) | ||

Half-shells on a 40' flatrack

The following example is a good illustration of the errors which can be made when loading such goods.

|

||

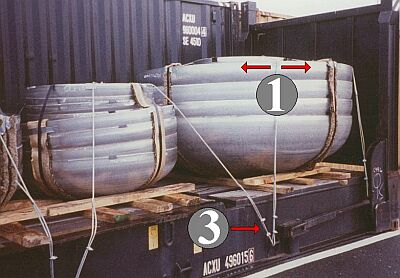

| Inadequately secured half-shells on a 40' flatrack | ||

These half-shells are secured nonuniformly with 16 mm diameter steel wire ropes. They are fitted in such a way that a lasting securing action cannot be guaranteed.

|

|

||

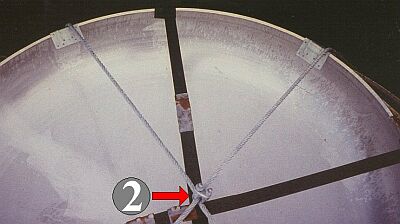

| Inadequately fixed half-shells | ||

Even slight lateral shifting of the steel wire ropes (1) can slacken the securing means. Fastening the ropes with only two wire clips (3) represents considerable wastage of material, due to the nonuniformity of the maximum securing loads. Moreover, most of the wire clips throughout the flatrack cargo are incorrectly positioned or inadequately tightened.

Displacement of the wire rope cannot be prevented by the wire clip (2) positioned at the point of intersection.

|

||

| Reduction in strength due to sharp edges | ||

The nonuniformity of the lashing is also caused by using inadequate edge protection. The sharpness of the half-shell edges weakens the steel wire ropes at the deflection points.

|

||

| The "gentle curves" in the cables are evidence of inadequate pretension |

||

In addition, the steel wire ropes are inadequately pretensioned. The gentle rounding at the deflection points is clearly visible. Sufficient pretensioning is particularly essential with the selected method of tie-down lashing.

The particular properties of steel wire ropes would in any case lead one to expect that the lashings will slacken in transit;

the reader is referred to the specific comments made in the section headed Lashing materials.

|

||

| Possible securing with claws | ||

Adequate securing of these half-shells on this flatrack could also be achieved by using claws, which are used as direct lashings and with which a completely tight fit is achieved.

The most cost-effective cargo securing option is to provide containers suitable for transporting half-shells. In the above case, recourse should have been made to flatracks with insertable stanchions.

Simple, quick, reasonably priced securing options are available, depending on the diameter of the half-shells: either the half-shells are positioned directly between two pairs of stanchions inserted parallel to the sides or the stanchions are modified beforehand by squared lumber fixed to the insides thereof in such a way that the half-shells can be fitted precisely between the four stanchions. Small stowage gaps can additionally be filled with board ends or the like.

To increase the strength of the stanchions and at the same time to provide the half-shells with a really tight-fitting "stanchion corset", crosswise lashing is provided between the "plain" stanchions and rectangular lashing is provided between the stanchions lined on the inside.

|

||

| Ideal securing conditions using flatracks with insertable stanchions | ||

|

||

| Crosswise and rectangular lashing of stanchions | ||

It would be worth checking whether it is possible to stow certain half-shells in half-height open-top containers and secure them with airbags. The following Figure is just a suggestion. The airbags must fit firmly. No sharp edges should be present; if the edges are sharp, they must be appropriately padded so that the airbags are not damaged.

|

||

| Possible use of airbags for securing | ||

Consideration should also be given to whether a combination of plywood sheets, boards and the like with airbags can provide adequate securing. This method would certainly be cheap.

|

||

| Top and selective enlargement below: Combination of plywood sheets and airbags for securing |

||