|

|

| Excessively large gaps in the stow |

These small gaps are enough for the bags, when exposed to the movement of the sea, gradually to work free under the relatively loosely shrink-wrapped cover and be abraded at the bottom on the pallet boards. If some of the bags are damaged and "bleed", they will create ever more free space which may result in damage to the remainder of the cargo. The gaps are there because of the dimensions of pool pallets. With dimensions of 800 mm x 1,200 mm, one pallet loaded crosswise and another longitudinally will together occupy a width of 1.2 m + 0.8 m = 2.00 m, while the internal width of the container is approx. 2.34 m, so leaving a gap of 34 cm.

|

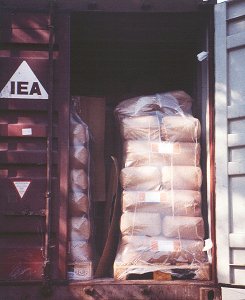

Unacceptably large gap in the stow and non-flush packed pallets |

Bigger gaps mean an even bigger risk. It is favorable if pallets are adapted to the container door dimensions and virtually match the internal dimensions. So that, during packing with forklift trucks, bags on any already loaded pallets are not damaged by pallets which have been lifted up for subsequent loading, it is worthwhile placing walking boards or hardboard sheets vertically between the pallets.

| Without separation by walking boards |  |

|

With separation by walking boards |

Some of the bags are so slackly filled that the lower layers have already been squashed. When packed in corrugated containers, such pallets can cause problems during unpacking as they may adapt to the shape of the corrugations, making them difficult to unpack.