Due to the low loading capacity of the plastic drums and the stowage gaps, the voyage could be a "wearing" one, since the gaps between sections 1 & 2 and 3 & 4 are too big:

|

||

| Inadequate packing in a 20' standard container | ||

The decision as to whether the plastic drums should be stowed at top or bottom depends essentially on a comparison of the case and drum masses. Primarily, the basic stowage rule "light on heavy" should be followed. Where the masses are virtually identical, the decision to adopt a particular stowage method should be based on the principle of "dry on wet", if the drums contain liquids. This principle is of little relevance in the case of pasty or powdery contents.

Depending on the contents of the drums, an acceptably packed container could look like this:

|

||

| Gap-free container section using pallets for securing | ||

The plywood cases are stowed to the left and right against the container side walls and the gap is filled with vertically positioned pallets (5). Interlayer dunnage consisting of walking boards (6) is laid on the cases, and the plastic drums are loaded on that. These are separated from the cargo to be packed subsequently with boards (7) fitted into the corrugations.

|

||

| Appropriate cargo dimensions ensure gap-free packing | ||

A stow is more cost-effective if the package dimensions fit the container. All that is needed here is for interlayer dunnage to be put in place and the drums to be separated from sections still to be packed.

|

||

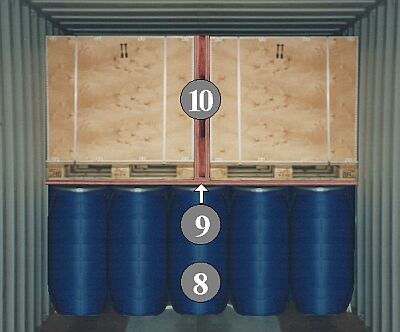

| Bracing of gaps in a 20' container | ||

The plastic drums (8) can be stowed in the bottom layer, if the plywood cases in the second layer are no heavier. It is essential to lay interlayer dunnage made from walking boards (9) or similar materials on the drums. The pallets with the plywood cases attached to them are placed in the second layer against the container side walls. The gap (10) remaining in the middle is braced.

|

||

| Appropriate cargo dimensions ensure gap-free packing | ||

Where masses are relatively great or relatively high inertia forces are to be anticipated, sections inside the container must not be separated by means of boards fitted into the corrugations, since the container may otherwise be damaged. A substitute method uses lattices, which are supported against parts of the container which have sufficient loading capacity. At any rate, the boards must be secured against sliding down.