|

|

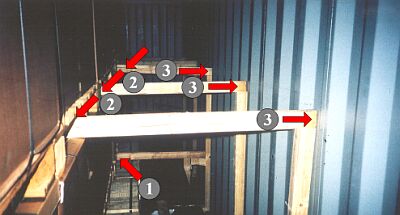

| Inadequate "securing" with squared lumber members |

An utter waste of materials. Just what is this "securing" intended to achieve? The wooden members (1) and (2) have just been inserted in the pallet-like package bases and fastened in place with nails.

The wooden members are exposing the container side wall to point loads at the ends (3) because the crosspieces are resting on the uprights.

Depending on the mass and nature of the cargo, appropriate securing might have looked like this:

|

|

| Proper securing |

The steel profiles (1) are stowed tightly to the left-hand container wall. Packages (2) and (3) are stacked on top of the profiles using interlayer dunnage (4) in the form of beams, boards or sheets. Squared lumber uprights (5) are placed in an appropriate number against this cargo and packages (6a), (6b) and (6c) are packed against these uprights. Squared lumber uprights (7) are set against the right-hand container side wall, the height of the uprights being determined by the forces to be absorbed. If severe stresses are anticipated, they are taken up to the container's top side rail. A lattice of boards (9) and (10) is fabricated (outside the container) and inserted into the gap between packages (6) and (8). The large space between the lattice and squared lumber uprights (7) is filled with cross braces (11). Lengthwise, nailed battens (12) or boards increase the stability of the bracing.