Load securing cannot be defined as simply the physical securing of a consignment using friction and tight-fit methods. Instead, it should be taken to be the "Safety of loads and protection against potential damage by loads" and should cover:

- protection of the goods against all forms of damage and/or

- protection of the environment against potentially damaging effects of the cargo.

- the characteristics of the goods that are being transported

- the construction and/or manufacturing features

- the types packing and packaging used

- the cargo transport units chosen for transportation

- the aids and devices used during packing

- the packing methods

- the securing methods

- the materials used to secure the load

- the finish of the materials used to secure the load

- the transport methods and routes used etc.

Note regarding legal stipulations

Packing of containers and cargo securing in or on containers must be carried out in accordance with the "CTU packing guidelines" published by the "International Maritime Organization". The exact title of the document is "IMO/ILO/UN ECE Guidelines for Packing of Cargo Transport Units (CTUs)".

The "Scope" section of the CTU guidelines contains information about situations where these guidelines are not applicable. This states:

-

They do not cover the filling or emptying of tank containers, portable tanks, or road tank vehicles, or the transport of any bulky cargo in bulk packagings.

|

|

| CTU guidelines do not apply to tanks and bulk cargo | |

The "Definitions" section defines a number of terms:

-

bulk cargoes means cargoes which are intended to be transported without any intermediate form of containment in bulk packagings or portable tanks.

-

cargo means any goods, wares, merchandise and articles of any kind which are intended to be transported.

-

dangerous cargoes means packaged, dangerous, hazardous or harmful substances, materials or articles, including environmentally hazardous substances (marine pollutants) and wastes, covered by the International Maritime Dangerous Goods (IMDG) Code. The term "dangerous cargoes" includes any empty uncleaned packagings.

| overpack means an enclosure used by a single shipper (defined in section 8 of the German "Carriage of Dangerous Goods by Sea Ordinance", GGVSee, as the "producer or shipper") to contain one or more packages and to form one unit for convenience of handling and stowage during transport. | |

| Examples of overpacks are a number of packages either: | |

| 1. | placed or stacked on to a load board such as a pallet and secured by strapping, shrink-wrapping, stretch-wrapping or other suitable means; or |

| 2. | placed in a protective outer packaging such as a case or crate; |

-

packaging(s) means receptacles and any other components or materials necessary for the receptacle to perform its containment function.

-

packages means the complete product of the packing operation, consisting of the packaging and its contents as prepared for transport.

|

|

||

| Faulty packaging will affect the entire duration of the transport | |||

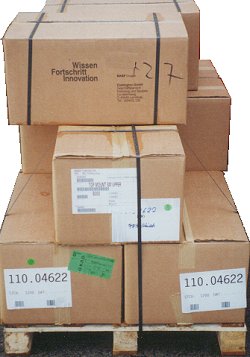

| unit load means a number of packages that are: | |

| 1. | placed or stacked on and secured by strapping, shrink-wrapping or other suitable means to a load board such as a pallet; |

| 2. | placed in a protective outer enclosure such as a pallet box; |

| 3. | permanently secured together in a sling. |

|

|

||

| Failure to implement unitization correctly makes packing and securing more difficult | |||

In the case of hazardous materials, the unitization shown on the left represents a failure to comply with the General Provisions of the IMDG code.

Unlike conventional methods of loading, closed containers offer better protection against robbery, theft and climate conditions. This is also a form of load securing or, to put it another way, protection of the load.

|

Loading containers in the rain |

For all moisture-sensitive cargoes, namely the vast majority of all general cargo, measures must be taken to ensure that the goods to be loaded are not stored in the open whether it be for long or short term storage, and that they are only packed in roofed areas.

The basic requirements for preventing damage and thus protecting the load are:

| 1. | container-suitable construction of loads, goods and/or packaging, including container-suitable palletization and unitization, as well as |

| 2. | the appropriate packing of the load into the container, and if this is not sufficient, |

| 3. | supplementing the packing measures by the use of suitable load securing mechanisms. |

If these three rules are observed, the container is able to carry out the protective function it was designed for. Failure to comply with these basic rules, however, means that the containers are endangered by their own cargo.

|

Damaged end wall, caused by a badly packed and unsecured cargo |

|

Palletization in a form not suitable for containers |

|

Palletization in a form suitable for containers |

The only criticism that can be leveled at the pallets is the way the straps have been placed and the fact that this has been carried out using steel strapping. The use of plastic strapping and edge protectors would have been preferable. Top marks, however, must be awarded for the fact that the second layer has been placed on top of interlayer dunnage.

This section of the Container Handbook has been designed to show the basics required in order to transport cargo without damaging it or anyone/anything else.

The "Scope" section of the CTU packing guidelines states:

-

These Guidelines are not intended to conflict with, or replace or supersede, any existing regulations or recommendations which may concern the carriage of cargo in CTUs.

-

The cargo must be in a state that does not permit it to present a danger to the safety of the railroad.

Load securing considerations are an issue as early as the design of products. The manufacturer intends selling their products. To do this, the goods are going to have to travel some distance - in particular goods designed for export. Since the manufacturer has a vested interest in getting their products to their customers in a undamaged state, it makes sense for the producer to enable or facilitate correct securing of the load by incorporating appropriate lashing points. Strictly speaking, the German Law on the Safety of Equipment, for instance, requires the manufacturer to do so.

Since once a load is passed on to the carriers, packing companies, cargo handlers, transport companies etc. the load is no longer in the power of disposal of the shipper, these companies are thus responsible for checking to ensure that the consignment is in a condition suitable for transportation. If faults are detected, measures must be taken to ensure that the goods are made suitable for transport (again).

In the case of hazardous goods, damaged packages must not be loaded under any circumstances. Instructions to the contrary should not be observed.